14 March 2022

Beyond the manufacturing method, glass is a solid solution resulting from the progressive solidification, without traces of crystallization, of homogeneous mixtures in fusion formed mainly by silica, soda and lime. To manufacture glass, three basic elements must be fused together:

-An OVERGLAZE, silica, introduced in the form of sand;

-A FLUX, soda or potash, in the form of sulphate or carbonate (lowers the melting temperature of silica);

-A STABILISER, lime, in the form of carbonate (gives the glass greater resistance to water attacks).

These three components are found in the compositions of glass since the most remote times. Today the most modern glass, produced in thousands of tons per day is the FLOAT GLASS. The glass obtained in this way, thanks to its extreme versatility and ability to be cut, grinded, hot-molded, hardened, finds today an increasingly widespread application in the construction industry, in the costume.

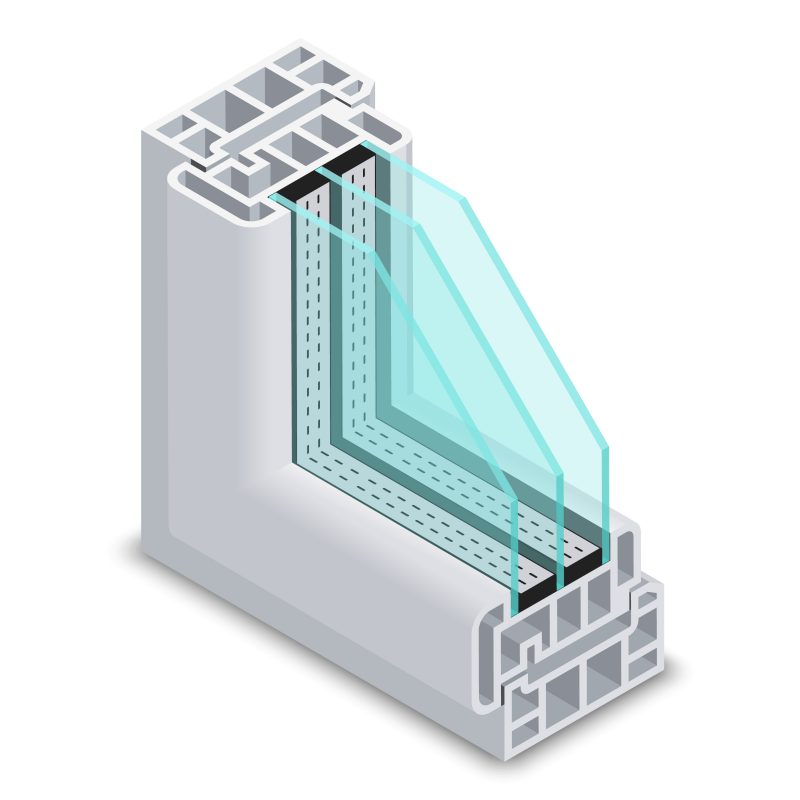

In construction, glass, due to its peculiar characteristics of transparency and surface hardness, represents the best response to the need for contact with the outside and, at the same time, protection from it, typical of modern man. More and more inserted in the structures often contributes in a preponderant way to determine the mechanical, acoustic and thermal characteristics.

Considering the composition and the history of glass, this material has been studied and reworked in an increasingly innovative and technological way based on all human needs. But the missing point between the history of glass and the issues of recycling and disposal that are at the heart of the SUNRISE project is still to be clarified. Glass is always considered as one of the most easily recyclable materials for its characteristics and properties. But if you look a little deeper, nowadays, treated glass stays out of the recycling market.

Treated glass, for example, is the glass used for car windows and windscreens and creates problems in its disposal and recycling. Among the types of treated glass, it is recognized the one that contains PVB (or Polyvinyl Butyral). PVB is a plastic film that ensures, through a technological process, the mechanical assembly of glass components in laminated products. It is a high-calorie polyolefin (plastic) consisting only of carbon, hydrogen and very little oxygen. It is a characteristic of glass that makes it difficult to recycle because the separation of glass from PVB itself is complicated management.

The SUNRISE project therefore wants to find a way to dispose not only of the glass, but also of the resin coating that covers the windows, in technical polyvinyl butyral (PVB). In this context, we can say that we started from the origins of glass that is commonly known to arrive then through technological innovations to a glass that is useful in many aspects for man but at the same time difficult to manage for the environment. This is where SUNRISE proves to be a key element in the recycling and reuse of material, even in its most complex facets.

Leave A Comment